Digicom Supports the Return of Electronic Assemblies Manufacturing Onshore with Prioritized Intellectual Property Protection |

|

|

Digicom is well positioned to support the ongoing trend to onshore electronics manufacturing back to America. Between the ever-increasing complexity of electronics supply chain and the economic turbulence caused by the COVID-19 pandemic, quality-assured onshore manufacturing is more important than ever ... Read details here |

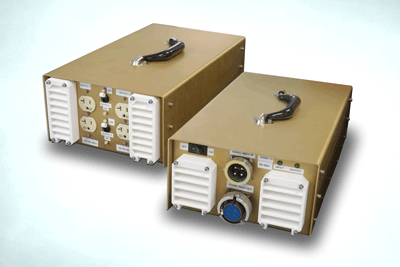

Digicom Electronics Introduces Portable, Lightweight, 400 Hz Power Converter for On-site Aircraft Maintenance |

|

|

Digicom Electronics Introduces Portable, Lightweight, 400 Hz Power Converter for On-site Aircraft Maintenance. The GENO 400 Hz Digicom Power Converter Model 779 accepts 100 VAC–250 VAC, 50 Hz, 60 Hz, and 400 Hz single, two, or 3-phase inputs and converts the power to 120 VAC 60 Hz output ... Read details here |

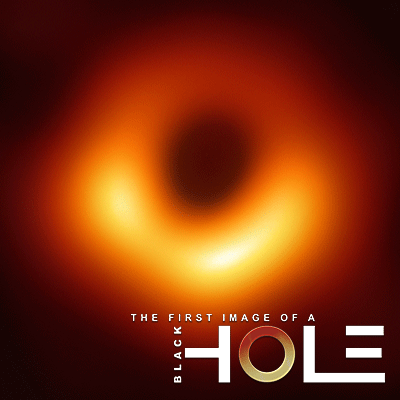

Digicom Electronics' ROACH System Captured the Data that Enabled Scientists to See the First Image of a Black Hole |

|

|

Digicom Electronics' Reconfigurable Open Architecture Computing Hardware (ROACH) System (the spectrometer system it builds for worldwide astronomers) was instrumental in collecting the data used to capture the first-ever photo of a Black Hole. The ROACH System, and Digicom's Diamond Track quality electronics manufacturing services and capabilities, will be on display at Space Tech Expo, Pasadena, CA, May 21 and 22, in booth 4023 ... Read details here |

Digicom Electronics Upgrades Quality Management system Certification to ISO 13485:2016 |

|

|

Digicom upgraded its Quality Management system to ISO 13485:2016. The ISO 13485 standard is a series of requirements that help device makers develop a quality management system to ensure the quality, safety, and effectiveness of the medical devices they manufacture ... Read details here |

Digicom Electronics and CASPER'S Technology Generate Astronomy and Aerospace Innovation and Collaboration, White Paper Available |

|

|

Digicom Electronics and CASPER technology open doors to astronomy and aerospace innovation. The white paper is now available ... Read details here |

Digicom Electronics Presents Ways to Mitigate Device Failure through Proper Manufacturing Processes, at BIOMEDevice, Booth 327 |

|

|

Digicom Electronics will present ways to mitigate device failure in manufacturing processes, at the BIOMEDevice Show, booth #327... Read details here |

Digicom Electronics Receives AS9100:2016 (RevD) Aerospace and ISO9001:2015 Certifications |

|

|

Digicom Electronics announces it has received aerospace certification AS9100:2016 (RevD) and ISO9001:2015, and is one of the first EMS companies to achieve it ... Read details here

|

Digicom Electronics Presents Ways to Improve Quality in the Electronics Assembly Process |

|

|

Digicom will present methods for improving product quality and integrity during the electronics assembly process at the Design-2-Part Show, being held in the Santa Clara Convention Center, Santa Clara, CA, on May 24 and 25, 2017, in booth 331 ... Read details here |

Digicom Electronics Presents EMS Diamond Track Defect Mitigation Services at BIOMEDevice Conference |

|

|

The program incorporates Digicom's proprietary Diamond Track nitrogen and cleaning services to reduce or eliminate defects in printed circuit boards, especially for mission critical products such as in the medical, military and aerospace, industrial, and RF wireless industries ... Read details here |

Digicom Electronics Incorporates Nitrogen in Soldering and Reflow Processes to Maximize Device Reliability |

|

|

Digicom Electronics now uses nitrogen in its Diamond Track Manufacturing soldering processes to minimize device failure and ensure printed circuit board integrity ... Read details here |

Digicom Electronics Presents Diamond Track EMS Services at the Design-2-Part Show, Santa Clara, CA |

|

|

Digicom presents its Diamond Track electronics manufacturing services at the Design-2-Part Show in Santa Clara, CA on June 8 and 9th, in booth 331. ... Read details here |

Digicom Electronics' Manufacturing Services for Medical Device Reliability to be on Display at BIOMEDevice 2015 |

|

|

Digicom will be presenting its Diamond Track Manufacturing Services for medical device reliability at the BIOMEDevice Show, San Jose, California on December 2nd and 3rd, booth 203 ... Read details here |

Digicom Electronics Expands Oakland, California EMS Facility |

|

|

Digicom has expanded its facility in Oakland, California in the San Francisco Bay area. In addition to doubling in size, Digicom has added even more advanced manufacturing equipment and additional personnel to increase manufacturing capacity and capabilities. ... Read details here |

Digicom Electronics Featured in Article, Personalized Care |

|

|

The D2P editor interviews several industry analysts and companies for the article and comes to the conclusion that many medical products that are now entering the commercial marketplace start with electronics, and the requirements for quality, reliability, and shorter lead times still predominate ... Read details and download article here |

Digicom Electronics' White Paper, Cleanliness of PCB Assemblies Leads to Medical Device Reliability, is Now Available |

|

|

Digicom Electronics announces that the white paper,announces that the white paper, Cleanliness of PCB Assemblies Leads to Medical Device Reliability, is now available. The paper explains how design and manufacturing conditions, along with myths about board cleanliness and contamination, have exacerbated the cleanliness problem, and shows how cleaning can eliminate board contamination for medical devices. Learn more |

Digicom Electronics' White Paper, What Medical Device Companies Need to Consider in Selecting an EMS Company, is Now Available |

|

|

Digicom Electronics announces that the white paper, What Medical Device Companies Need to Consider in Selecting an EMS Company, is now available on the Digicom Electronics website. The article discusses the factors that contribute to a successful contract electronics manufacturing relationship and the things a medical device company needs to keep in mind and consider during the selection process. The article details the steps to take in selecting the contract manufacturer best suited to handle the design, prototyping, material selection and purchasing, manufacturing, test, process validation, shipping and logistics, and/or other special needs of a medical device company. Read more |

Digicom Electronics Awarded ITAR Certification ~ EMS can contract to manufacture defense-related projects |

|

|

Digicom Electronics announces that it has received International Traffic in Arms Regulations (ITAR) certification. ITAR is a set of United States government regulations that control the export and import of defense-related articles and services on the United States munitions list. Learn more |

Digicom Electronics Provides Medical Device Companies with Complete Solutions from Design for Manufacturing to Fully Integrated Box Build |

|

|

Digicom Electronics has designed a Diamond Track Program to help medical device companies with their complete process from design for manufacturing to fully integrated box builds. Consultations Available at the BIOMEDevice Show, San Jose, CA, Booth 503. Get details |

Digicom Hosts Sustainable Business Alliance Green Electronics Event |

|

|

Digicom Electronics is hosting a special Sustainable Business Alliance "Green Electronics" event. Learn more |

Digicom Electronics Debuts Redesigned Website: Videos and articles for more informed EMS selection |

|

|

Digicom Electronics announces the availability of its new, multi-faceted website. The website features video clips of each process stage, articles, and information to assist those seeking an EMS in making a more informed selection. Learn more |

Digicom Electronics Wins 2012 Global Technology Award for its Diamond Track Cleaning Process ~ Process eliminates PCB failures that result from contamination |

|

|

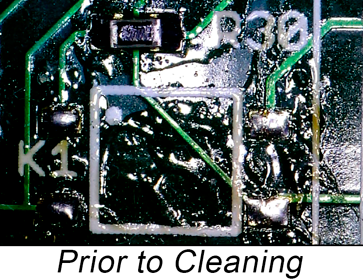

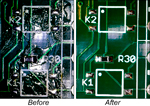

Digicom Electronics, a technology and quality-driven electronics manufacturing services company, has won the 2012 Global Technology Award in the category of Contract Services for its new Diamond Track Cleaning Process. Read more |

Digicom Electronics' Cleaning Process Exceeds Standards by 75%; Zero Ion Contamination Found on the PCB |

|

|

Independent tests show that Digicom's boards test 75% cleaner than the IPC's highest level of clean. In addition, a recent lab analysis for ion contamination found zero ion contamination (zero levels of sodium chloride - NaCl Micrograms/sq.in.) on assembled boards. This level of cleaning eliminates failures caused by board contamination. Learn more |

Digicom Electronics Expands Contract Manufacturing Services and Capabilities - Relocates to new facility in Oakland, CA |

|

|

Digicom Electronics collaborated in the design, development, prototyping, sourcing, manufacture and test, and produced the finished, fully-compliant product. The system was developed for space science and research applications. Read here |

Digicom's Diamond Track Process Enhances Product and Process Control, Productivity, and Quality |

|

|

Digicom Electronics introduces its new Diamond Track Process, a multifaceted approach to quality and productivity, at IPC APEX 2012. Diamond Track processes include design services, advanced cleaning, selective soldering, process control, inspection and testing, and certification and process validation. Learn more |

Digicom Electronics White Paper "Process Validation 101" Now Available |

|

|

Digicom explains the importance of process validation in ensuring that a process consistently produces a product that meets its specifications, in a white paper titled Process Validation 101. The paper describes why a process requires validation, the three primary steps of process validation, and a common mistake to avoid in documentation. When done correctly, process validation can save a considerable amount of time, money, and resources. Learn more |

Digicom Electronics Highlights ROACH at Pacific Design and Manufacturing (MDM) West |

|

|

Digicom Electronics collaborated in the design, development, prototyping, sourcing, manufacture and test, and produced the finished, fully-compliant product. The system was developed for space science and research applications. Read here |

Digicom Electronics Achieves Certification to 9001:2008 and ISO 13485:2003 |

|

|

Digicom Electronics was recently presented with its ISO 9001:2008 and ISO 13485:2003 certificates from Intertek, affirming that Digicom's operations adhere to internationally-recognized standards for quality management. Learn more |

"Digicom Electronics and CASPER'S Technology Open Endless Possibilities for Astronomy and Aerospace Innovation and Collaboration."

Today, CASPER technology powers over 45 scientific instruments worldwide. A significant contribution to these innovations comes from Digicom Electronics and its ROACH system. Read it here.

"Process Validation 101," an important component in the design, prototyping and manufacturing process and one, if done correctly, that can save a considerable amount of time, money and resources. Free white paper.

"Cleanliness of PCB Assemblies Leads to Medical Device Reliability," is now available for download.

Kaynes Technology Expands U.S. Presence with Strategic Acquisition of Digicom Electronics. Kaynes Technology's high-volume production merges with Digicom's prototyping and small-batch expertise, offering comprehensive solutions across both the US and India. Read more here

Kaynes Technology Expands U.S. Presence with Strategic Acquisition of Digicom Electronics. Kaynes Technology's high-volume production merges with Digicom's prototyping and small-batch expertise, offering comprehensive solutions across both the US and India. Read more here

Digicom Supports the Return of Electronic Assemblies Manufacturing Onshoring with Prioritized Intellectual Property Protection. Digicom is well positioned to support the ongoing trend to onshore electronics manufacturing back to America. Read more here

Digicom Supports the Return of Electronic Assemblies Manufacturing Onshoring with Prioritized Intellectual Property Protection. Digicom is well positioned to support the ongoing trend to onshore electronics manufacturing back to America. Read more here

Digicom's ROACH System Captured the Data that Enabled Scientists to See the First Image of a Black Hole. Digicom has worked with the Collaboration for Astronomy Signal Processing and Electronics Research (CASPER), the Event Horizon Telescope (EHT) project, the University of California Berkeley, and many other institutes, researchers, engineers, and scientists from around the world for more than a decade. Read more here

Digicom Electronics Introduces Portable, Lightweight, 400 Hz Power Converter for On-site Aircraft Maintenance. Digicom Electronics Introduces Portable, Lightweight, 400 Hz Power Converter for On-site Aircraft Maintenance. Details here

Digicom Electronics Introduces Portable, Lightweight, 400 Hz Power Converter for On-site Aircraft Maintenance. Digicom Electronics Introduces Portable, Lightweight, 400 Hz Power Converter for On-site Aircraft Maintenance. Details here

Digicom Electronics announces it has received aerospace cerfication AS9100:2016 (RevD) & ISO 9001:2015, and is one of the first EMS companies to achieve it. Learn more

Digicom Electronics announces it has received aerospace cerfication AS9100:2016 (RevD) & ISO 9001:2015, and is one of the first EMS companies to achieve it. Learn more