With increased component miniaturization, electromigration and the rising cost of advanced packages, it is essential to thoroughly clean today's high reliability electronics.

Digicom's process uses a unique customized, in-line cleaning system that repeatedly delivers zero ion contamination as measured and backed by independent certified lab reports.

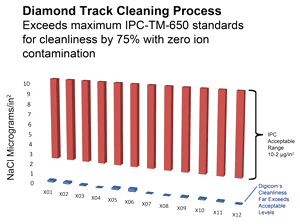

Independent tests show that Digicom's Diamond Track process results in boards that are 75% cleaner than the IPC's* highest level of clean. A recent lab analysis for ion contamination found zero ion contamination (zero levels of sodium chloride–NaCl Micrograms/sq.in.) on assembled boards. The process is completely "green". Deionized water from polishing tanks is used and recycled. Filters catch the solids while powerful blowers ensure that harsh chemicals are not blown back into the tank. Clear windows enable the operator to monitor the entire process. A refractometer checks the stability of the tank to make sure it's not compromised. All drained solids are environmentally friendly.

Independent tests show that Digicom's Diamond Track process results in boards that are 75% cleaner than the IPC's* highest level of clean. A recent lab analysis for ion contamination found zero ion contamination (zero levels of sodium chloride–NaCl Micrograms/sq.in.) on assembled boards. The process is completely "green". Deionized water from polishing tanks is used and recycled. Filters catch the solids while powerful blowers ensure that harsh chemicals are not blown back into the tank. Clear windows enable the operator to monitor the entire process. A refractometer checks the stability of the tank to make sure it's not compromised. All drained solids are environmentally friendly.

The cleaning process is repeatable, reliable, and uses an advanced in-line cleaning system to increase speed and throughput. All boards are routinely run through the system prior to assembly to ensure that the soldering process is not compromised by any contaminates from board fabrication and after assembly to completely clean any remaining chemicals from the soldering process. With Digicom's unique Diamond Track Cleaning the customers' products are much less susceptible to corrosion-induced failures reducing the need for maintenance or repair. The cost savings to Digicom's customers, especially those with military, aerospace and medical device applications, is considerable. The Diamond Track process eliminates failures from contamination that often result in millions of dollars in rework and repair, recalls, lawsuits, and lost business and revenue, and it protects the company's brand and reputation.

The cleaning process is repeatable, reliable, and uses an advanced in-line cleaning system to increase speed and throughput. All boards are routinely run through the system prior to assembly to ensure that the soldering process is not compromised by any contaminates from board fabrication and after assembly to completely clean any remaining chemicals from the soldering process. With Digicom's unique Diamond Track Cleaning the customers' products are much less susceptible to corrosion-induced failures reducing the need for maintenance or repair. The cost savings to Digicom's customers, especially those with military, aerospace and medical device applications, is considerable. The Diamond Track process eliminates failures from contamination that often result in millions of dollars in rework and repair, recalls, lawsuits, and lost business and revenue, and it protects the company's brand and reputation.

* IPC Association is a global trade organization and leading source for industry standards, training, market research and public policy advocacy. Ref: IPC-TM-650 Standard for Cleanliness.

"Digicom Electronics and CASPER'S Technology Open Endless Possibilities for Astronomy and Aerospace Innovation and Collaboration."

Today, CASPER technology powers over 45 scientific instruments worldwide. A significant contribution to these innovations comes from Digicom Electronics and its ROACH system. Read it here.

"Process Validation 101," an important component in the design, prototyping and manufacturing process and one, if done correctly, that can save a considerable amount of time, money and resources. Free white paper.

"Cleanliness of PCB Assemblies Leads to Medical Device Reliability," is now available for download.

Digicom Supports the Return of Electronic Assemblies Manufacturing Onshoring with Prioritized Intellectual Property Protection. Digicom is well positioned to support the ongoing trend to onshore electronics manufacturing back to America. Read more here

Digicom Supports the Return of Electronic Assemblies Manufacturing Onshoring with Prioritized Intellectual Property Protection. Digicom is well positioned to support the ongoing trend to onshore electronics manufacturing back to America. Read more here

Digicom's ROACH System Captured the Data that Enabled Scientists to See the First Image of a Black Hole. Digicom has worked with the Collaboration for Astronomy Signal Processing and Electronics Research (CASPER), the Event Horizon Telescope (EHT) project, the University of California Berkeley, and many other institutes, researchers, engineers, and scientists from around the world for more than a decade. Read more here

Digicom Electronics Introduces Portable, Lightweight, 400 Hz Power Converter for On-site Aircraft Maintenance. Digicom Electronics Introduces Portable, Lightweight, 400 Hz Power Converter for On-site Aircraft Maintenance. Details here

Digicom Electronics Introduces Portable, Lightweight, 400 Hz Power Converter for On-site Aircraft Maintenance. Digicom Electronics Introduces Portable, Lightweight, 400 Hz Power Converter for On-site Aircraft Maintenance. Details here

Digicom Electronics announces it has received aerospace cerfication AS9100:2016 (RevD) & ISO 9001:2015, and is one of the first EMS companies to achieve it. Learn more

Digicom Electronics announces it has received aerospace cerfication AS9100:2016 (RevD) & ISO 9001:2015, and is one of the first EMS companies to achieve it. Learn more